The C61400 Copper Aluminum Bronze Alloy possess good mechanical and ductility properties. With having good resistance against corrosion, this alloy is suitable for the applications that carried out in high load and high-pressure conditions.

The C61400 Copper Aluminum Bronze Alloy possess good mechanical and ductility properties. With having good resistance against corrosion, this alloy is suitable for the applications that carried out in high load and high-pressure conditions.

Applications :

• Fasteners : Threaded Members, Stringers, Bolts, Nuts

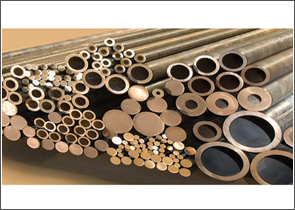

• Industrial : Piping Systems, Structural Components, Machine Parts, Corrosion Resistant Vessels, Sea Water Piping, Condenser Tube and Piping Systems, Tube Sheets, Welded Pipe, Seamless Tubing and Pipe, Chutes for Abrasive Grains, Heat Exchanger Tubes, Mining Shovels, Tanks, Condenser Head Plates

• Marine : Fasteners, Protective Sheathing, Pressure Vessels, Marine Hardware, Welded Tanks

• Ordinance : Blending Chambers

Specifications |

Designation |

ISO |

CuAl8Fe3 |

Europen |

CuAl8Fe3 |

BS |

AS 106 |

JIS |

C 6140 |

Al |

Cu |

Fe |

Pb |

Mn |

P |

Zn |

|

Min/Max |

6.0 - 8.0 |

Rem |

1.5 - 3.5 |

0.01 |

1 |

0.015 |

0.2 |

Nominals |

7.0000 |

91.0000 |

2.0000 |

- |

- |

- |

- |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Good |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

40 |

Machinability rating |

20 |

Oxyacetylene Welding |

Not Recommended |

Seam Weld |

Good |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.285 lb/in3 @ 68 F |

7.89 gm/cm3 @ 20 C |

Electrical Conductivity |

14 %IACS @ 68 F |

0.082 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

74.1 ohms-cmil/ft @ 68 F |

12.32 microhm-cm @ 20 C |

Melting Point Liquid US |

1915 F |

1046 C |

Melting Point Solid US |

1905 F |

1041 C |

Modulas of Elasticity in Tension |

17000 ksi |

117000 MPa |

Modulas of Rigidity |

6400 ksi |

44130 MPa |

Specific Gravity |

7.89 |

7.89 |

Specific Heat Capacity |

0.09 Btu/lb/°F @ 68 F |

377.1 J/kg · °K at 293 K |

Thermal Conductivity |

39.0 Btu · ft/(hr · ft2 ·°F) @ 68 F |

67.5 W/m · °K at 20 C |

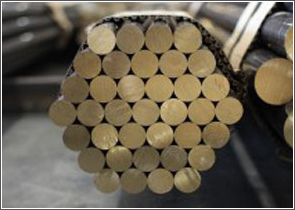

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C61800 contains 89% copper, 10% aluminum and 1% iron. The alloy is moderate in strength and ductility and can be worked in both hot as well as cold successfully. It possess resistance to corrosion in different environments and is applicable in the manufacturing of bushings, bearings, corrosion-resistant components and welding rod.

The aluminum bronze C61800 contains 89% copper, 10% aluminum and 1% iron. The alloy is moderate in strength and ductility and can be worked in both hot as well as cold successfully. It possess resistance to corrosion in different environments and is applicable in the manufacturing of bushings, bearings, corrosion-resistant components and welding rod.

Specifications |

Designation |

European |

CuAl10Fe1 |

Cu(1) |

Al |

Fe |

Pb |

Si |

Zn |

|

Min/Max |

Rem |

8.5-11.0 |

.50-1.5 |

.02 |

.10 |

.02 |

Nominals |

89.0 |

10.0 |

1.0 |

- |

- |

- |

Joining Technique |

Suitability |

Soldering |

Fair |

Brazing |

Good |

Oxyacetylene Welding |

Not Recommended |

Gas Shielded Arc Welding |

Good |

Coated Metal Arc Welding |

Good |

Spot Weld |

Good |

Seam Weld |

Good |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Fair |

Capacity for Being Hot Formed |

Good |

Forgeability Rating |

50 |

Machinability Rating |

40 |

Product |

Specification |

Electrode, Welding |

AWS A5.6 |

Rod, Welding |

AWS A5.7, A5.15, A5.13 |

Wire |

AWS A5.7 |

Wire, Metallizing |

MILITARY MIL-W-6712 |

Melting Point - Liquidus°F |

1913 |

Melting Point - Solidus°F |

1904 |

Densitylb/cu in. at 68°F |

0.272 |

Specific Gravity |

7.53 |

Electrical Conductivity% IACS at 68°F |

13 |

Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F |

37 |

Coefficient of Thermal Expansion 68-57210?6 per °F (68 – 572°F) |

9 |

Specific Heat CapacityBtu/ lb /°F at 68°F |

0.09 |

Modulus of Elasticity in Tensionksi |

17000 |

Modulus of Rigidityksi |

6400 |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C62300 is used while manufacturing valve and pump components for industrial process streams, marine equipment, high strength fasteners and pole line hardware.

The aluminum bronze C62300 is used while manufacturing valve and pump components for industrial process streams, marine equipment, high strength fasteners and pole line hardware.

Applications :-

Al |

Cu |

Fe |

Mn |

Ni |

Si |

Sn |

|

Min/Max |

8.5 - 10.0 |

Rem |

2.0 - 4.0 |

0.5 |

1 |

0.25 |

0.6 |

Nominals |

10 |

87 |

3 |

- |

- |

- |

- |

End Product |

Specification |

Bar |

AMS 4635, ASME SB150, ASTM B150, SAE J463, J461 |

Bar, Forging |

ASTM B124 |

Forgings, Die |

AMS 4635, ASTM B283, MILITARY MIL-B-16166, SAE J463, J461 |

Rod |

AMS 4635, ASME SB150, ASTM B150, SAE J463, J461 |

Rod, Forgings |

ASTM B124 |

Shapes |

ASTM B150 |

Shapes, Forging |

ASTM B124 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Good |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

75 |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

50 |

Oxyacetylene Welding |

Not Recommended |

Seam Weld |

Good |

Soldering |

Not Recommended |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.277 lb/in3 @ 68 F |

7.67 gm/cm3 @ 20 C |

Electrical Conductivity |

12 %IACS @ 68 F |

0.07 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

86.4 ohms-cmil/ft @ 68 F |

14.36 microhm-cm @ 20 C |

Melting Point Liquid US |

1915 F |

1046 C |

Melting Point Solid US |

1905 F |

1041 C |

Modulas of Elasticity in Tension |

17000 ksi |

117000 MPa |

Modulas of Rigidity |

6400 ksi |

44130 MPa |

Specific Gravity |

7.67 |

7.67 |

Specific Heat Capacity |

0.09 Btu/lb/°F @ 68 F |

377.1 J/kg · °K at 293 K |

Thermal Conductivity |

31.0 Btu · ft/(hr · ft2 ·°F) @ 68 F |

53.7 W/m · °K at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C62300 and C62400 is used while manufacturing valve and pump components for industrial process streams, marine equipment, high strength fasteners and pole line hardware.

The aluminum bronze C62300 and C62400 is used while manufacturing valve and pump components for industrial process streams, marine equipment, high strength fasteners and pole line hardware.

Applications :-

Al |

Cu |

Fe |

Mn |

Si |

Sn |

|

Min (%) |

10.0 - 11.5 |

Rem |

2.0 - 4.5 |

0.3 |

0.25 |

0.2 |

Max (%) |

11.0000 |

86.0000 |

3.0000 |

- |

- |

- |

End Product |

Specification |

Forgings |

SAE J463, J461 |

Rod |

ASTM B150 |

Rod, Welding |

AWS A5.7 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Excellent |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

80 |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

50 |

Oxyacetylene Welding |

Not Recommended |

Seam Weld |

Good |

Soldering |

Not Recommended |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.269 lb/in3 at 68 F |

7.45 gm/cm3 @ 20 C |

Electrical Conductivity |

12 %IACS @ 68 F |

0.07 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

86.4 ohms-cmil/ft @ 68 F |

14.36 microhm-cm @ 20 C |

Melting Point Liquid US |

1900 F |

1038 C |

Melting Point Solid US |

1880 F |

1027 C |

Modulas of Elasticity in Tension |

17000 ksi |

117000 MPa |

Modulas of Rigidity |

6400 ksi |

44130 MPa |

Specific Gravity |

7.45 |

7.45 |

Specific Heat Capacity |

0.09 Btu/lb/°F @ 68 F |

377.1 J/kg · °K at 293 K |

Thermal Conductivity |

34.0 Btu · ft/(hr · ft2 ·°F) @ 68 F |

58.8 W/m · °K at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C62500 is high in corrosion resistance alloy, which is used while manufacturing guide bushings, wear strips, cams, dies, forming rolls, sheet metal forming dies, wing dies for vertical tube benders, bushings, wear plates for plastic molds, welding rod, plastic mold components.

The aluminum bronze C62500 is high in corrosion resistance alloy, which is used while manufacturing guide bushings, wear strips, cams, dies, forming rolls, sheet metal forming dies, wing dies for vertical tube benders, bushings, wear plates for plastic molds, welding rod, plastic mold components.

Applications :

Cu |

Al |

Fe |

Mn |

|

Min/Max |

Rem |

12.5-13.5 |

3.5-5.5 |

2.0 |

Nominals |

82.7 |

13.0 |

4.3 |

- |

End Product |

Specification |

Rod, Welding |

AWS A5.13 |

Joining Technique |

Suitability |

Soldering |

Not Recommended |

Brazing |

Fair |

Oxyacetylene Welding |

Not Recommended |

Gas Shielded Arc Welding |

Good |

Coated Metal Arc Welding |

Good |

Spot Weld |

Fair |

Seam Weld |

Fair |

Butt Weld |

Fair |

Capacity for Being Cold Worked |

Not Recommended |

Capacity for Being Hot Formed |

Excellent |

Forgeability Rating |

80 |

Machinability Rating |

20 |

Product Property |

US Customary |

Metric |

Melting Point - Liquidus |

1925 F |

1052 C |

Melting Point - Solidus |

1917 F |

1047 C |

Density |

0.260 lb/in3 at 68 F |

7.2 gm/cm3 @ 20 C |

Specific Gravity |

7.21 |

7.21 |

Electrical Resistivity |

104 ohms-cmil/ft @ 68 F |

17.29 microhm-cm @ 20 C |

Electrical Conductivity |

10 %IACS @ 68 F |

0.059 MegaSiemens/cm @ 20 C |

Thermal Conductivity |

27 Btu · ft/(hr · ft2·oF)at 68F |

46.7 W/m · oK at 20 C |

Coefficient of Thermal Expansion |

9 ·10-6 per oF (68-572 F) |

16.2 ·10-6 per oC (20-300 C) |

Specific Heat Capacity |

0.090 Btu/lb/oF at 68 F |

377.1 J/kg · oK at 293 K |

Modulas of Elasticity in Tension |

16000 ksi |

110000 MPa |

The aluminum bronze C95200 is used in the manufacturing of electrical, fasteners, industrial, marine and ordnance.

The aluminum bronze C95200 is used in the manufacturing of electrical, fasteners, industrial, marine and ordnance.

Typical Uses for C37700 Forging Brass :-

Specifications |

Designation |

ISO |

CuAl0Fe3 |

Europen |

CuAlFe2-B/C |

BS |

CuAl10Fe3 |

JIS |

CAC701 |

Russian |

BrA9Z3L/BrA10Z3 |

Joining Technique |

Suitability |

Brazing |

Good |

Coated Metal Arc Welding |

Good |

Gas Shielded Arc Welding |

Excellent |

Machinability Rating |

20 |

Oxyacetylene Welding |

Not Recommended |

Soldering |

Good |

Al |

Cu |

Fe |

|

Min/Max |

8.5-9.5 |

86.0 min |

2.5-4.0 |

Nominals |

9.0000 |

87.7000 |

3.3000 |

End Product |

Specification |

Centrifugal |

ASME SB271, ASTM B271, SAE J461, J462 |

Continuous |

ASME B505, ASTM B505, SAE J461, J462 |

Flanges |

ASME B16.24, SB148, ASTM B148 |

Ingot |

ASTM B30 |

Sand |

ASME SB148, ASTM B763, B148, SAE J461, J462 |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 ·10-6 per oC (20-300 C) |

Density |

0.276 lb/in3 at 68 F |

7.64 gm/cm3 @ 20 C |

Electrical Conductivity |

11 %IACS @ 68 F |

0.064 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

94.0 ohms-cmil/ft @ 68 F |

15.63 microhm-cm @ 20 C |

Magnetic Permeability |

1.1 |

1.2 |

Melting Point - Liquidus |

1913 F |

1045 C |

Melting Point - Solidus |

1907 F |

1042 C |

Modulas of Elasticity in Tension |

15000 ksi |

103400 MPa |

Poisson's Ratio |

0.31 |

0.31 |

Specific Gravity |

7.64 |

7.64 |

Specific Heat Capacity |

0.09 Btu/lb/oF at 68 F |

377.1 J/kg · oK at 293 K |

Thermal Conductivity |

29.1 Btu · ft/(hr · ft2·oF)at 68F |

50.4 W/m · oK at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C95400 is also called C954. It is the most popular and all purpose high yield aluminum bronze alloy with high tensile strength, ductility, welding ability and resistance to wear, fatigue and deformation under shock or overload. The alloy is used while manufacturing bearings, gears, valve components, wear-plate and wear-strip in conformation with continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

The aluminum bronze C95400 is also called C954. It is the most popular and all purpose high yield aluminum bronze alloy with high tensile strength, ductility, welding ability and resistance to wear, fatigue and deformation under shock or overload. The alloy is used while manufacturing bearings, gears, valve components, wear-plate and wear-strip in conformation with continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

Typical Uses for C954 Aluminum Bronze:

Specifications |

Designation |

Italy |

CuAl11Fe4 |

Al |

Cu |

Fe |

Mn |

Ni |

|

Min/Max |

10.0-11.5 |

83.0 min |

3.0-5.0 |

0.5 |

1.5 |

Nominals |

10.8000 |

83.2000 |

4.0000 |

- |

- |

End Product |

Specification |

Centrifugal |

ASME SB271, ASTM B271, SAE J462, J461 |

Continuous |

ASTM B505, SAE J462, J461 |

Ingot |

ASTM B30 |

Permanent |

ASTM B806 |

Precision |

MILITARY MIL-C-11866 |

Sand |

ASME SB148, ASTM B66, B148, B763, SAE J461, J462 |

Joining Technique |

Suitability |

Brazing |

Good |

Coated Metal Arc Welding |

Good |

Gas Shielded Arc Welding |

Good |

Machinability Rating |

60 |

Oxyacetylene Welding |

Not Recommended |

Soldering |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 ·10-6 per oC (20-300 C) |

Density |

0.269 lb/in3 at 68 F |

7.45 gm/cm3 @ 20 C |

Electrical Conductivity |

13 %IACS @ 68 F |

0.75 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

80.2 ohms-cmil/ft @ 68 F |

13.33 microhm-cm @ 20 C |

Magnetic Permeability (As Cast) |

1.27 |

1.27 |

Magnetic Permeability (TQ50 temper) |

1.2 |

1.2 |

Melting Point – Liquidus |

1900 F |

1038 C |

Melting Point – Solidus |

1880 F |

1027 C |

Modulas of Elasticity in Tension |

15500 ksi |

107000 MPa |

Specific Gravity |

7.45 |

7.45 |

Specific Heat Capacity |

0.1 Btu/lb/oF at 68 F |

419.0 J/kg · oK at 293 K |

Thermal Conductivity |

33.9 Btu · ft/(hr · ft2·oF)at 68F |

58.7 W/m · oK at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze C95900 is characterized by its high strength and excellent corrosion resistance. The uses of the alloy includes variety of heavy duty mechanical and structural products including gears, worm drives, valve guides and seats. It is a heavy duty bearing alloy, but does not tolerate misalignment or dirty lubricants and generally should be used against hardened steel shafts, with both shaft and bearing machined to fine surface finishes.

The aluminum bronze C95900 is characterized by its high strength and excellent corrosion resistance. The uses of the alloy includes variety of heavy duty mechanical and structural products including gears, worm drives, valve guides and seats. It is a heavy duty bearing alloy, but does not tolerate misalignment or dirty lubricants and generally should be used against hardened steel shafts, with both shaft and bearing machined to fine surface finishes.

Typical Uses for C95900 Aluminum Bronze :-

Al |

Cu |

Fe |

Mn |

Ni |

|

Min/Max |

12.0-13.5 |

Rem |

3.0-5.0 |

1.5 |

0.5 |

Nominals |

12.7000 |

- |

4.0000 |

- |

- |

End Product |

Specification |

Centrifugal |

ASTM B271 |

Continuous |

ASTM B505 |

Ingot |

ASTM B30 |

Sand |

ASTM B148 |

Density (lbs/in3) |

.260 |

Specific Gravity |

7.21 |

Specific Heat(Btu/lb 0F) |

.09 |

Coefficient of Thermal Expansion(in/in/0F) |

9.0 x 10-6 |

Electrical Conductivity(% IACS) |

10 |

Electrical Resistivity (Microhms-Meter @ 680F) |

172 |

Thermal Conductivity(Btu/sq. ft./ft./hr./0F @ 680F) |

22.5 |

Magnetic Permeability |

1 |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The aluminum bronze CuAl11Ni5Fe5 is used in aeronautical industry, due to its high mechanical properties and oxidation resistance. The alloy CuAl11Ni5Fe5 is resistant to corrosion in saline mist area.

The aluminum bronze CuAl11Ni5Fe5 is used in aeronautical industry, due to its high mechanical properties and oxidation resistance. The alloy CuAl11Ni5Fe5 is resistant to corrosion in saline mist area.

Typical Uses for CUAL11NI5FE5 Aluminum Bronze :-

Specifications |

Designation |

Europen |

CuAl11Fe6Ni6 |

Germany |

CuAl11Ni6Fe5 |

|

Al |

Cr |

Co |

Cu |

Fe |

Pb |

Mn |

Ni |

Sn |

Zn |

Min/Max |

10.0 - 11.0 |

0.05 |

0.2 |

74.5 min |

4.0 - 5.5 |

0.03 |

1.5 |

4.2 - 6.0 |

0.25 |

0.3 |

Nominals |

10.5 |

- |

- |

- |

4.7 |

- |

- |

5.1 |

- |

- |

Product Property |

Value |

Density |

7.58 g/cm³ |

Melting Point |

1035 °C |

Modulus of Elasticity |

115 GPa |

Thermal Conductivity |

37.7 W/m.K |

Mechanical Property |

Value |

Proof Stress |

400-530 MPa |

Tensile Strength |

600-760 MPa |

Elongation A50 mm |

15-5 % |

Hardness Vickers |

170 to 220 HV |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |