Spec Equivalents: AMS 4640, SAE J463, QQ-C-465B, ASME SB150, ASTM B-150, B-124, B-171, B-283

Spec Equivalents: AMS 4640, SAE J463, QQ-C-465B, ASME SB150, ASTM B-150, B-124, B-171, B-283

C63000 (AMS 4640 - CDA 630) Nickel Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the strength of alloy without effecting its excellent ductility, toughness and corrosion resistance. Typical applications for C63000 nickel aluminum bronze included aircraft landing gear components, strut bearings, main pistons, trunnion bearings and similar vital components.

Typical Uses :

• Industrial: Hydraulic Bushings for Earth Moving Equipment, Corrosion Resistant Articles, Bushings, Bearings, Heat Exchanger Flanges, Heat Exchanger Headers, Tanks, Valve Balls, Structural Members, Pump Shafts, Aircraft Parts, Valve Guides, Plunger Tips, Welded Piping Systems, Balls, Gears, Cams, Pump Parts, Shafting, Condenser Tube for Power Stations and Desalting Units, Valve Seats

• Marine : Pump Parts, Bolts, Nuts, Propellers, Ship Propellers

• Plumbing : Faucets

Specifications |

Designation |

ISO |

CuAl0Ni5Fe4 |

European |

CuAl0Ni5Fe4 |

BS |

CA 104 |

JIS |

C 6301 |

Russian |

BrAZN10.4.4 |

|

Al |

Cu |

Fe |

Mn |

Ni |

Si |

Sn |

Zn |

Min/Max |

9.0 - 11.0 |

Rem |

2.0 - 4.0 |

1.5 |

4.0 - 5.5 |

0.25 |

0.2 |

0.3 |

Nominals |

10 |

82 |

3 |

- |

5 |

- |

- |

- |

End Product |

Specification |

Bar |

AMS 4640, ASME SB150, ASTM B150, FEDERAL QQ-C-450, SAE J463, J461 |

Bar, Forging |

ASTM B124 |

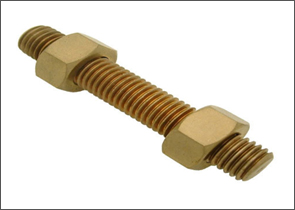

Bolts |

ASTM F468 |

Forgins, Die |

AMS 4640, ASTM B283, MILITARY MIL-B-16166 |

Nuts |

ASTM F467 |

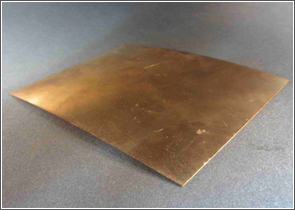

Plate |

ASTM B171, FEDERAL QQ-C-450 |

Plate, Condenser Tube |

ASME SB171, ASTM B171 |

Rod |

AMS 4640, ASME SB150, ASTM B150, SAE J463, J461 |

Rod, Forging |

ASTM B124 |

Screws |

ASTM F468 |

Shapes |

AMS 4640, ASTM B150, SAE J463, J461 |

Shapes, Forging |

ASTM B124 |

Sheet |

FEDERAL QQ-C-450 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

75 |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

30 |

Oxyacetylene Welding |

Not recommended |

Seam Weld |

Good |

Soldering |

Not recommended |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.274 lb/in3 @ 68 F |

7.58 gm/cm3 @ 20 C |

Electrical Conductivity |

7 %IACS @ 68 F |

0.041 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

116.0 ohms-cmil/ft @ 68 F |

19.28 microhm-cm @ 20 C |

Melting Point Liquid US |

1930 F |

1054 C |

Melting Point Solid US |

1895 F |

1035 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

AMS 4590

AMS 4590

The C63020 Nickel Aluminum Bronze alloy possess high ductility, high electrical and thermal conductivity, high impact strength, good creep resistance, ease of welding, and low volatility under high vacuum.

Typical Uses :

• Industrial: Bearings, Bushings, Valve Balls, Forming Dies for Roll Bearings, Hydraulic Bushings for Earth Moving Equipment, Valve Parts - Cryogenic

Specifications |

Designation |

ISO |

CuAl0Ni5Fe4 |

European |

CuAl0Ni5Fe4 |

BS |

CA 104 |

JIS |

C 6301 |

Russian |

BrAZN10.4.4 |

|

Al |

Cr |

Co |

Cu |

Fe |

Pb |

Si |

Ni |

Sn |

Zn |

Min/Max |

10.0 - 11.0 |

0.05 |

0.2 |

74.5 min |

4.0 - 5.5 |

0.03 |

1.5 |

4.2 - 6.0 |

0.25 |

0.3 |

Nominals |

10.5 |

- |

- |

- |

4.7 |

- |

- |

5.1 |

- |

- |

End Product |

Specification |

Bar |

ASTM B150 |

Pipe |

ASTM B315 |

Rod |

ASTM B150 |

Shapes |

AMS 4590, ASTM B150 |

Tube |

ASTM B315 |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

ASTM B150, QQ-C-465

ASTM B150, QQ-C-465

The C63200 Nickel Aluminum Bronze alloy possess superior salt water corrosion resistance. It also is resistant to cavitation and erosion. Along with the advantage of pressure tightness, this high strength alloy is excellent for welding and is available in many forms at a lower cost to you.

Typical Uses :

Specifications |

Designation |

ISO |

CuAl9Fe4Ni4 |

UNS |

C63280 |

Czech Republic |

CuAl9Fe4Ni4 |

|

Al |

Cu |

Fe |

Pb |

Mn |

Ni |

Si |

Min/Max |

8.7 - 9.5 |

Rem |

3.5 - 4.3 |

0.02 |

1.2 - 2.0 |

4.0 - 4.8 |

0.1 |

Nominals |

9 |

82 |

4 |

- |

1.6 |

4.4 |

- |

End Product |

Specification |

Bar |

ASTM B150 |

Bar, Forging |

ASTM B124 |

Electrode, Welding |

AWS A5.6, MILITARY MIL-E-23765/3 |

Forgings, Die |

ASTM B283 |

Plate |

ASTM B171 |

Rod |

ASTM B150 |

Rod, Forging |

ASTM B124 |

Shapes |

ASTM B150 |

Shapes, Forging |

ASTM B124 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Fair |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

70 |

Gas Sheilded Arc Welding |

Excellent |

Machinability rating |

30 |

Oxyacetylene Welding |

Not Recommended |

Seam Weld |

Fair |

Soldering |

Fair |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.276 lb/in3 @ 68 F |

7.64 gm/cm3 @ 20 C |

Electrical Conductivity |

7 %IACS @ 68 F |

0.041 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

148.0 ohms-cmil/ft @ 68 F |

24.6 microhm-cm @ 20 C |

Melting Point Liquid US |

1940 F |

1060 C |

Melting Point Solid US |

1905 F |

1041 C |

Modulas of Elasticity in Tension |

17000 ksi |

117000 MPa |

Modulas of Rigidity |

6400 ksi |

44130 MPa |

Specific Gravity |

7.64 |

7.64 |

Specific Heat Capacity |

.105 Btu/lb/°F @ 68 F |

440.0 J/kg · °K at 293 K |

Thermal Conductivity |

20.0 Btu · ft/(hr · ft2 ·°F) @ 68 F |

34.6 W/m · °K at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

ASTM B505

ASTM B505

C95500 Nickel Aluminum Bronze 9D is available with salt water corrosion resistance. It also is resistant to cavitation and erosion. Along with the advantage of pressure tightness, this high strength alloy is excellent for welding and is available in many forms at a lower cost to you.

Typical Uses :

|

Al |

Cu |

Fe |

Mn |

Ni |

Min/Max |

10.0-11.5 |

78.0 min |

3.0-5.0 |

3.5 |

3.0-5.5 |

Nominals |

11.0000 |

80.0000 |

4.0000 |

- |

4.3000 |

End Product |

Specification |

Centrifugal |

ASTM B271, SAE J462, J461 |

Continuous |

ASTM B505, SAE J462, J461 |

Ingot |

ASTM B30 |

Precision |

ASTM B806 |

Sand |

ASTM B148, B763, SAE J461, J462 |

Joining Technique |

Suitability |

Brazing |

Good |

Coated Metal Arc Welding |

Not Recommended |

Gas Shielded Arc Welding |

Not Recommended |

Machinability Rating |

40 |

Oxyacetylene Welding |

Not Recommended |

Soldering |

Excellent |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 ·10-6 per oC (20-300 C) |

Density |

0.272 lb/in3 at 68 F |

7.53 gm/cm3 @ 20 C |

Electrical Conductivity |

8 %IACS @ 68 F |

0.049 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

122.8 ohms-cmil/ft @ 68 F |

20.41 microhm-cm @ 20 C |

Magnetic Permeability (As Cast) |

1.32 |

1.32 |

Magnetic Permeability (TQ50 temper) |

1.2 |

1.2 |

Melting Point - Liquidus |

1930 F |

1054 C |

Melting Point - Solidus |

1900 F |

1038 C |

Modulas of Elasticity in Tension |

16000 ksi |

110000 MPa |

Poisson's Ratio |

0.32 |

0.32 |

Specific Gravity |

7.53 |

7.53 |

Specific Heat Capacity |

0.1 Btu/lb/oF at 68 F |

419.0 J/kg · oK at 293 K |

Thermal Conductivity |

24.2 Btu · ft/(hr · ft2·oF)at 68F |

41.9 W/m · oK at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

Applications :

Applications :

Specifications |

Designation |

BS |

CA104 |

EN |

CW307G |

JIS |

C6301 |

DIN |

2.0966 |

ISO |

CuAl10Ni5Fe4 |

Russian (GOST) |

|

Cu |

Pb |

Sn |

Zn |

Fe |

Ni |

Al |

Mg |

Mn |

Si |

Min/Max |

REM. |

0.05 |

0.10 |

0.40 |

4.0-6.0 |

4.0-6.0 |

8.50-11.0 |

0.05 |

0.05 |

0.10 |

Specifications :

Ingots |

|

Bar |

|

Square |

|

Billets |

|

Plate |

|

Sheet |

|

Flat |

|

Rods |

|

Profiles |

|

Wire |

|

Hollows |

|

Hex |

|

Tubes |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Fair |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Gas Shielded Arc Welding |

Excellent |

Machinability Rating |

30 |

Oxyacetylene Welding |

Fair |

Seam Weld |

Fair |

Soldering |

Fair |

Spot Weld |

Good |

Forgeability Rating |

70 |

Form |

Tensile N/mm2(min) |

0.2% Proof Stress N/mm2 (min) |

Elogation on 5.65 gauge length % |

Izod Value J (min) |

<15 mm Dia |

680 |

325 |

17 |

- |

15 mm – 25 mm Dia |

680 |

325 |

17 |

24 |

25 mm – 100 mm Dia |

635 |

295 |

17 |

27 |

>100 mm Dia |

620 |

245 |

15 |

23 |

Melting Point |

1035oC |

Density |

7.5 g/cm3 |

Specific Gravity |

|

Electrical Conductivity 20C |

7 – 10 IACS |

Thermal Conductivity |

37.7 – 42 W/m.K |

Coefficient of Thermal Expansion 20-300 |

18 x 10-6 |

Specific Heat Capacity |

|

Modulus of Elasticity |

115 GPa |

Modulus of Rigidity |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

The C95800 Alpha Nickel Aluminum Bronze is corrosion resistant against salt water, cavitation and erosion. The alloy is having the advantage of pressure tightness and is excellent for welding. It is available in many forms at a lower cost to you.

The C95800 Alpha Nickel Aluminum Bronze is corrosion resistant against salt water, cavitation and erosion. The alloy is having the advantage of pressure tightness and is excellent for welding. It is available in many forms at a lower cost to you.

Cast ASTM: B271, B505, B148 Military/AMS: MIL-B-24480 Other: ABS - 4T

Common Applications :

Specifications |

Designation |

ISO |

CuAl10Fe5Ni5 |

European |

CuAl10Fe5Ni5 |

BS |

CuAl10Fe5Ni5 |

JIS |

C AC703 |

Russian |

BrA10ZN4L |

|

Al |

Cu |

Fe |

Pb |

Mn |

Ni |

Si |

Min/Max |

8.5-9.5 |

79.0 min |

3.5-4.5 |

0.03 |

.8-1.5 |

4.0-5.0 |

0.1 |

Nominals |

9 |

81 |

4 |

- |

1 |

4.5 |

- |

End Product |

Specification |

Centrifugal |

ASTM B271, SAE J462, J461 |

Continuous |

ASTM B505, SAE J461, J462 |

Ingot |

ASTM B30 |

Precision |

ASTM B806 |

Sand |

ASTM B806 |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 ·10-6 per oC (20-300 C) |

Density |

0.276 lb/in3 at 68 F |

7.64 gm/cm3 @ 20 C |

Electrical Conductivity |

7 %IACS @ 68 F |

0.041 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

146.7 ohms-cmil/ft @ 68 F |

34.39 microhm-cm @ 20 C |

Information not available on website |

|

|

Magnetic Permeability |

1.05 |

1.05 |

Melting Point - Liquidus |

1940 F |

1060 C |

Melting Point - Solidus |

1910 F |

1043 C |

Modulas of Elasticity in Tension |

16500 ksi |

114000 MPa |

Poisson's Ratio |

0.32 |

0.32 |

Specific Gravity |

7.64 |

7.64 |

Specific Heat Capacity |

0.105 Btu/lb/oF at 68 F |

440.0 J/kg · oK at 293 K |

Thermal Conductivity |

20.8 Btu · ft/(hr · ft2·oF)at 68F |

36.0 W/m · oK at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

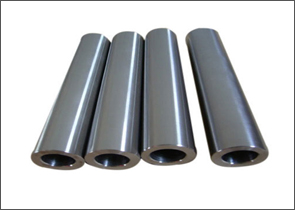

C96900 Nickel Tin Bronze Spinodal

C96900 Nickel Tin Bronze SpinodalC96900 Nickel Tin Bronze Spinodal is ideal for using in tough environments. The alloy possess high strength, anti-galling properties, non-magnetic, excellent machinability, corrosion resistance and good bearing properties.

It is used in bushings and bearings for aircraft, industrial equipment, and heavy equipment. It is also used for oil and gas drilling hardware including rotary steerable housings, kelly valve seats and pressure housings.

C96900 in the hot worked and spinodally hardened (AT/TX00) condition exhibits tensile strength up to 140 ksi in a copper nickel tin alloy with excellent machinability.

Typical Uses :

|

Cu |

Ni |

Fe |

Mn |

Nb |

Pb |

Sn |

Zn |

Min/Max |

Reminder |

14.5-15.5 |

0.05 max |

.05-.3 max |

0.1 max |

0.02 max |

7.5-8.5 |

0.5max |

Nominals |

- |

- |

|

|

|

|

|

|

Density |

0.325 |

Lbs. per cubic inch @ 68°F (annealed) |

Modulus |

21 |

Elastic modulus in tension x 106 P.S.I. |

Electrical Conductivity |

9 |

% IACS at 68°F (annealed) |

Thermal Conductivity |

22 |

BTU per foot per hour per °F at 68°F (annealed) |

Thermal Expansion |

9.1 |

Inches per inch x 10-6 from 68°F to 572°F |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

AMS 4640

AMS 4640

CuAL10Ni5Fe4 (AMS 4640) Nickel Aluminum Bronze alloy is an good choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance. Typical applications include aircraft landing gear components, strut bearings, main pistons, trunnion bearings and similar vital components.

Typical Uses :

Specifications |

Designation |

ISO |

CuAl0Ni5Fe4 |

European |

CuAl0Ni5Fe4 |

BS |

CA 104 |

JIS |

C 6301 |

Russian |

BrAZN10.4.4 |

|

Al |

Cu |

Fe |

Mn |

Ni |

Si |

Sn |

Zn |

Min/Max |

9.0 - 11.0 |

Rem |

2.0 - 4.0 |

1.5 |

4.0 - 5.5 |

0.25 |

0.2 |

0.3 |

Nominals |

10 |

82 |

3 |

- |

5 |

- |

- |

- |

End Product |

Specification |

Bar |

AMS 4640, ASME SB150, ASTM B150, FEDERAL QQ-C-450, SAE J463, J461 |

Bar, Forging |

ASTM B124 |

Bolts |

ASTM F468 |

Forgins, Die |

AMS 4640, ASTM B283, MILITARY MIL-B-16166 |

Nuts |

ASTM F467 |

Plate |

ASTM B171, FEDERAL QQ-C-450 |

Plate, Condenser Tube |

ASME SB171, ASTM B171 |

Rod |

AMS 4640, ASME SB150, ASTM B150, SAE J463, J461 |

Rod, Forging |

ASTM B124 |

Screws |

ASTM F468 |

Shapes |

AMS 4640, ASTM B150, SAE J463, J461 |

Shapes, Forging |

ASTM B124 |

Sheet |

FEDERAL QQ-C-450 |

Strip |

FEDERAL QQ-C-450 |

Tube |

AMS 4640 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

75 |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

30 |

Oxyacetylene Welding |

Not recommended |

Seam Weld |

Good |

Soldering |

Not recommended |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.274 lb/in3 @ 68 F |

7.58 gm/cm3 @ 20 C |

Electrical Conductivity |

7 %IACS @ 68 F |

0.041 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

116.0 ohms-cmil/ft @ 68 F |

19.28 microhm-cm @ 20 C |

Melting Point Liquid US |

1930 F |

1054 C |

Melting Point Solid US |

1895 F |

1035 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |

AMS 4640

AMS 4640

CW307G (AMS 4640) Nickel Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance. Typical applications include aircraft landing gear components, strut bearings, main pistons, trunnion bearings and similar vital components.

Typical Uses :

Specifications |

Designation |

ISO |

CuAl0Ni5Fe4 |

European |

CuAl0Ni5Fe4 |

BS |

CA 104 |

JIS |

C 6301 |

Russian |

BrAZN10.4.4 |

|

Al |

Cu |

Fe |

Mn |

Ni |

Si |

Sn |

Zn |

Min/Max |

9.0 - 11.0 |

Rem |

2.0 - 4.0 |

1.5 |

4.0 - 5.5 |

0.25 |

0.2 |

0.3 |

Nominals |

10.0000 |

82.0000 |

3.0000 |

- |

5.0000 |

- |

- |

- |

End Product |

Specification |

Bar |

AMS 4640, ASME SB150, ASTM B150, FEDERAL QQ-C-450, SAE J463, J461 |

Bar, Forging |

ASTM B124 |

Bolts |

ASTM F468 |

Forgins, Die |

AMS 4640, ASTM B283, MILITARY MIL-B-16166 |

Nuts |

ASTM F467 |

Plate |

ASTM B171, FEDERAL QQ-C-450 |

Plate, Condenser Tube |

ASME SB171, ASTM B171 |

Rod |

AMS 4640, ASME SB150, ASTM B150, SAE J463, J461 |

Rod, Forging |

ASTM B124 |

Screws |

ASTM F468 |

Shapes |

AMS 4640, ASTM B150, SAE J463, J461 |

Shapes, Forging |

ASTM B124 |

Sheet |

FEDERAL QQ-C-450 |

Strip |

FEDERAL QQ-C-450 |

Tube |

AMS 4640 |

Joining Technique |

Suitability |

Brazing |

Fair |

Butt Weld |

Good |

Capacity for Being Cold Worked |

Poor |

Capacity for Being Hot Formed |

Good |

Coated Metal Arc Welding |

Good |

Forgeability Rating |

75 |

Gas Sheilded Arc Welding |

Good |

Machinability rating |

30 |

Oxyacetylene Welding |

Not recommended |

Seam Weld |

Good |

Soldering |

Not recommended |

Spot Weld |

Good |

Product Property |

US Customary |

Metric |

Coefficient of Thermal Expansion |

9.0 ·10-6 per oF (68-572 F) |

16.2 · 10 6? per °C (20-300 C) |

Density |

0.274 lb/in3 @ 68 F |

7.58 gm/cm3 @ 20 C |

Electrical Conductivity |

7 %IACS @ 68 F |

0.041 MegaSiemens/cm @ 20 C |

Electrical Resistivity |

116.0 ohms-cmil/ft @ 68 F |

19.28 microhm-cm @ 20 C |

Melting Point Liquid US |

1930 F |

1054 C |

Melting Point Solid US |

1895 F |

1035 C |

Modulas of Elasticity in Tension |

17500 ksi |

121000 MPa |

Modulas of Rigidity |

6400 ksi |

44130 MPa |

Specific Gravity |

7.58 |

7.58 |

Specific Heat Capacity |

0.09 Btu/lb/°F @ 68 F |

377.1 J/kg · °K at 293 K |

Thermal Conductivity |

22.6 Btu · ft/(hr · ft2 ·°F) @ 68 F |

39.1 W/m · °K at 20 C |

ROUND RODS |

8mm To 70 mm |

HEX |

10mm To 60mm |

SQUARE |

10mm To 60mm |

FLAT |

10mm Min Thickness and max Width 120mm |

BILLETS |

Up to 200 mm |

INGOTS |

As per Specification |