Copper nickel alloys, also known as Cu-Ni, offers excellent corrosion resistance, especially in marine salt water environments. Copper nickel alloys that are generally chosen for sea water parts and service equipment contains 10 to 30 percent nickel.

Tremor Alloys stocks C70600 and C71500 Copper Nickel pipes, which are commonly used in seawater piping due to its complete resistance to barnacles. Due to Its resistance of various sea organisms, this alloy makes seawater desalination, water systems, fire fighting systems, and similar applications very reliable.

These various alloys also have important additions of iron and manganese, which are necessary to maintain good corrosion resistance in the harsh environments. Aside from being very corrosion resistant to sea water, copper nickel alloys are very thermally stable. Copper nickel is most commonly used in applications such as electrical and electronic products, tubes for condensers in ships and power plants, various marine products, including valves, pumps, fittings, and sheathing for ship hulls.

APPLICATIONS

Marine hardware

Desalination

Seawater piping systems

Cooling loops

Pipe nipples

ASTM B151, MIL C15726F, SAE J461, SAE J463, Class 200

ASTM B151, MIL C15726F, SAE J461, SAE J463, Class 200

C70600 (C706) & C71500 (C715), Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some of the primary uses for C706 include copper nickel fittings (CuNi Fittings) as well as condensers and exchanger shells

Typical Uses for C706 Copper Nickel "90/10":

AUTOMOTIVE: Power Steering Tube, Brake Lines

CONSUMER: Screw Lamp Bases

INDUSTRIAL: Condenser Plates, Condensers, Weld Torch Tips, Heat Exchanger Tubes, Valve Bodies, Evaporator Tubes, Pressure Vessels, Distiller Tubes, Pump Impellers for Oil Refining, Ferrules, Evaporators

MARINE: Boat Hulls, Tube Sheet for Salt Water Service, Salt Water Pipe Fittings, Salt Water Piping Systems, Salt Water Piling Wrap, Hot Water Tanks, Salt Water Baffles, Propeller Sleeves, Ship Hulls, Water Hoses

PLUMBING: Flanges

Sizes Available From Tremor Alloys

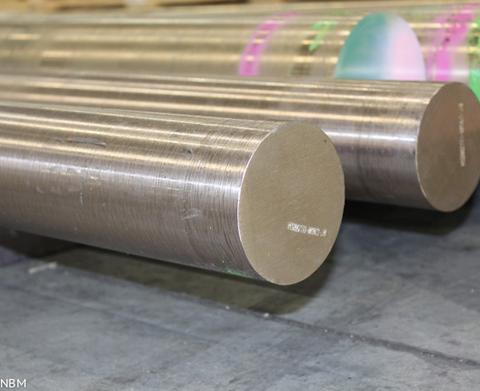

SOLID BAR: 1/4" - 12" diameter

PLATE: up to 6" thick

ASTM B151, MIL C15726F, SAE J461, SAE J463

ASTM B151, MIL C15726F, SAE J461, SAE J463

C70600 & C71500, Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, and pump components.

Typical Uses for CDA 715 Copper Nickel "70/30":

INDUSTRIAL: Pump Impellers, Heat Exchanger Tubes, Evaporator Tubes, Distiller Tubes, Condenser Plates, Refrigerators, Process Equipment, Condenser Components, Ferrules, Welding Backing Rings, Flexible Metal Hose, Weld Wire, Boiler Parts, Condensers, Propeller Sleeves, Heat Exchanger Components

MARINE: Salt Water Flanges, Salt Water Piping, Valve Bodies, Sea Water Service, Fittings, Sea Water Condensers, Salt Water Pipe Fittings, Water Boxes - Salt Water Applications, Pump Bodies and Internal Parts-Sea Water

Sizes Available From Tremor Alloys

SOLID BAR . . . . . . . . . . 1/4" - 12" diameter

PLATE . . . . . . . . . . . . . . . up to 6" thick

ASTM B151, MIL C15726F

ASTM B151, MIL C15726F

Offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

Typical Uses for CuNi10Fe1Mn Copper Nickel:

AUTOMOTIVE: Power Steering Tube, Brake Lines

CONSUMER: Screw Lamp Bases

INDUSTRIAL: Condenser Plates, Condensers, Weld Torch Tips, Heat Exchanger Tubes, Valve Bodies, Evaporator Tubes, Pressure Vessels, Distiller Tubes, Pump Impellers for Oil Refining, Ferrules, Evaporators

MARINE: Boat Hulls, Tube Sheet for Salt Water Service, Salt Water Pipe Fittings, Salt Water Piping Systems, Salt Water Piling Wrap, Hot Water Tanks, Salt Water Baffles, Propeller Sleeves, Ship Hulls, Water Hoses

PLUMBING: Flanges

.jpg) ASTM B151, MIL C15726F

CuNi10Fe1Mn, Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

ASTM B151, MIL C15726F

CuNi10Fe1Mn, Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

CuNi10Fe1Mn, Copper nickel also has important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

Typical Uses for CuNi10Fe1Mn Copper Nickel:

AUTOMOTIVE: Power Steering Tube, Brake Lines

CONSUMER: Screw Lamp Bases

INDUSTRIAL: Condenser Plates, Condensers, Weld Torch Tips, Heat Exchanger Tubes, Valve Bodies, Evaporator Tubes, Pressure Vessels, Distiller Tubes, Pump Impellers for Oil Refining, Ferrules, Evaporators

MARINE: Boat Hulls, Tube Sheet for Salt Water Service, Salt Water Pipe Fittings, Salt Water Piping Systems, Salt Water Piling Wrap, Hot Water Tanks, Salt Water Baffles, Propeller Sleeves, Ship Hulls, Water Hoses

PLUMBING: Flanges

.jpg) ASTM B151, MIL C15726F

ASTM B151, MIL C15726F

CuNi30Fe1Mn Copper Nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

Typical Uses for CuNi30Fe1Mn:

INDUSTRIAL: Pump Impellers, Heat Exchanger Tubes, Evaporator Tubes, Distiller Tubes, Condenser Plates, Refrigerators, Process Equipment, Condenser Components, Ferrules, Welding Backing Rings, Flexible Metal Hose, Weld Wire, Boiler Parts, Condensers, Propeller Sleeves, Heat Exchanger Components

MARINE: Salt Water Flanges, Salt Water Piping, Valve Bodies, Sea Water Service, Fittings, Sea Water Condensers, Salt Water Pipe Fittings, Water Boxes - Salt Water Applications, Pump Bodies and Internal Parts-Sea Water